The Guardian™ Proximity System is an innovative solution designed to address the challenges faced by drivers operating in challenging environments with poor visibility. The system provides a cost-effective, reliable means to detect proximity, ensuring safety and efficiency in underground operations.

Designed for underground environments, Guardian™ operates seamlessly through curtains, is tamper resistant, and provides detection accuracy within inches with auto-adjusting detection coverage areas. No driver intervention needed – just controlled safe stops.

Ditch the shortcomings of legacy proximity detection systems and move to the advantages offered by Guardian. Legacy proximity systems present several challenges that impede their effectiveness in underground environments. These challenges include widely varying detection zones, making it difficult to ensure consistent coverage. Moreover, susceptibility to electromagnetic interference poses a significant obstacle, particularly in mine settings with numerous sources of electromagnetic activity such as AC power lines and electric motors.

Maintenance of these systems is often expensive and complex, and personnel are asked to wear cumbersome, bulky tags. Addressing these challenges is crucial for advancing proximity detection technology to meet the needs of mine operations today.

IWT’s Guardian™ Proximity System redefines safety for underground mining with advanced high-bandwidth technology for collision prevention without driver assistance, setting a new standard for mobile haulage safety in the mining industry.

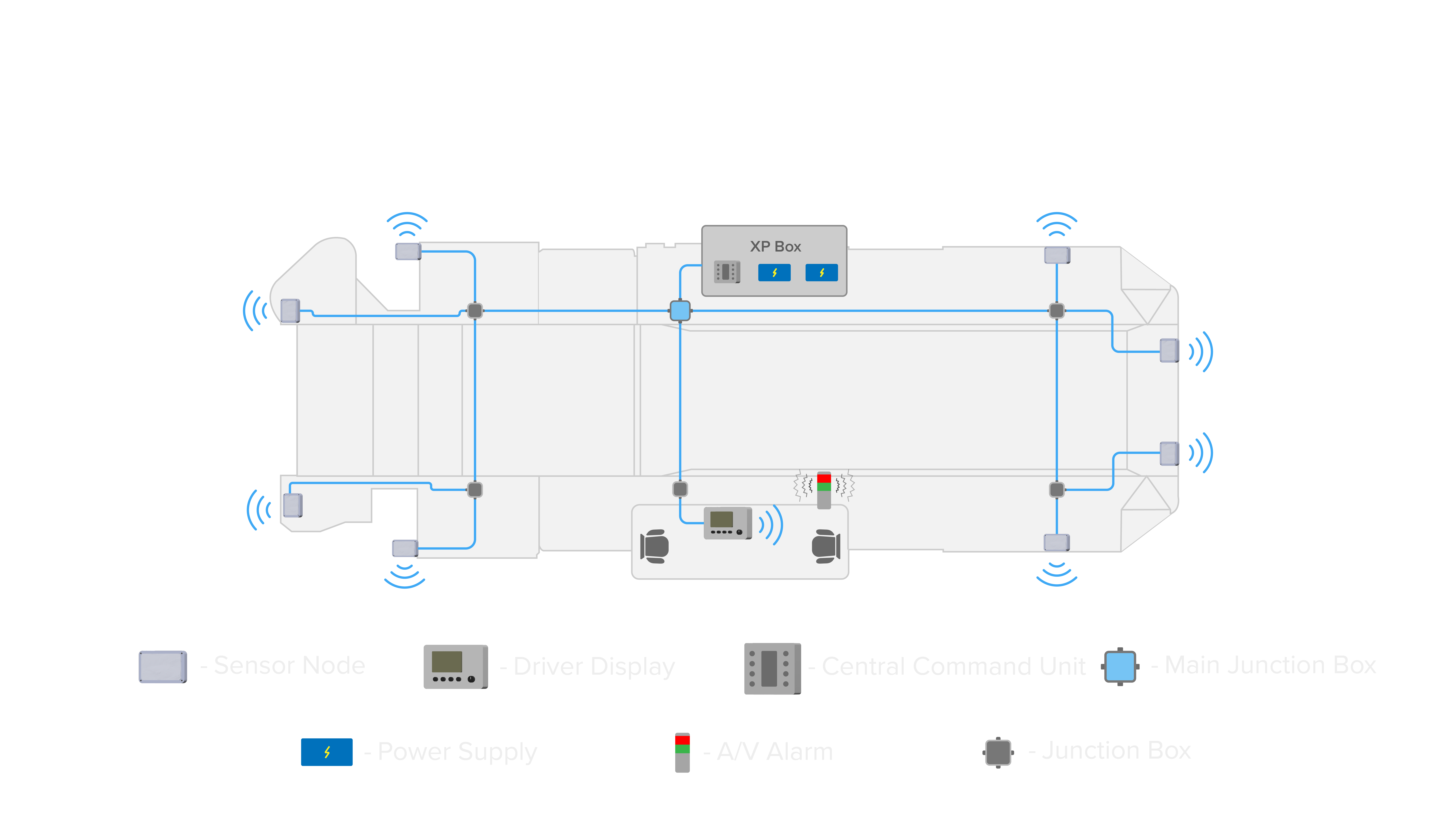

The main system components include:

Ensuring personnel safety and complying with regulatory standards are paramount considerations for the operation of underground vehicles, making the implementation of a proximity detection system indispensable. From a personnel safety perspective, the confined and often complex environments in underground settings pose inherent risks. A proximity detection system serves as a critical tool in mitigating these risks by providing real-time alerts to operators when they are near personnel or obstacles. This proactive approach significantly reduces the likelihood of accidents. At the end of the day, all workers should go home to family and friends.

Beyond personnel safety, regulatory compliance is a key driver for the adoption of proximity detection systems on underground vehicles. Increased awareness of vehicle-related deaths and injuries have prompted a legislative regulation review in many states. Incorporating a proximity detection system not only aligns with these regulatory requirements, but also demonstrates a commitment to prioritizing safety measures.

By integrating Guardian™ Proximity Systems into underground vehicles, operators can ensure compliance with industry standards, fostering a safer working environment and avoiding potential legal consequences associated with non-compliance.

The adoption of proximity detection systems is both a pragmatic safety measure and a strategic move to meet regulatory obligations in the operation of underground vehicles.

Accidents involving underground coal haulage machines and scoops have resulted in 49 deaths from 1984 to 2021.

The Guardian system is designed to be used with a variety of mobile haulage equipment and is being commercially launched by IWT to the meet the MSHA proposed requirements for permissible use on Shuttle Cars. However, this technology is adaptable to other uses, and IWT is currently scoping requirements to market the Guardian system for other mobile haulage equipment.

The main components of the Guardian system are miner, driver, continuous miner operator proximity tags, vehicular-mounted sensors, a driver display unit, and vehicular control unit.

Guardian uses RF high-bandwidth transceivers to communicate the location (relative to the vehicle) and distance of miner, the driver, and the continuous miner operator tags to the shuttle car sensors. RF transceivers continuously track the tags within the coverage areas, updating the relative location and distance many times per second. This information, in turn, is used by the vehicular control unit to slow or stop the shuttle.

The Guardian system can be tuned to meet customer operational requirements for individual mines and can be used to limit vehicular speeds on a per system basis. In a typical deployment, a mine may have a forward warning that, at full speed, begins warning miners of an approaching Shuttle Car 50 to 75 feet away. As the car get closer, it will automatically decrease in speed and at 20 feet will be completely stopped.

The miner tag that is within the braking coverage area will illuminate with a yellow warning light and a warning sound will be emitted by the tag. The sensors on the shuttle car will also illuminate with a yellow warning light. As the distance between the miner and the Shuttle Car continues to decrease, the car will brake to a full stop. At this point the tag and sensors will illuminate with a red light. As the miner moves away from the shuttle car, the tag will illuminate green, indicating that they are no longer in a breaking area and the car will be able to resume travel.

A miner, driver, or continuous miner operator can check out any tag at the beginning of the shift. All tags are issued as miner tags, and a driver or continuous miner operator must assign their role to their tag on the shuttle car through the Guardian display unit on the shuttle car.

The Guardian™ Proximity System offers a cost-effective way to enhance safety and meet regulatory compliance. For a limited time only, take advantage of our Early Adopter Promotion with early adopter discounts for quantity system procurement before MSHA approval is finalized.

Make IWT’s Guardian™ Proximity System your trusted partner for maximized underground safety.

Contact us today to take advantage of early adopter discounts.

See the Guardian Proximity System’s journey from development to delivery.

Ready for a safer underground operation? Contact us for more information, demonstrations, and early adopter promotions.